When It Comes to Precision, Desoutter's Automated Robot Guidance Leads the Way

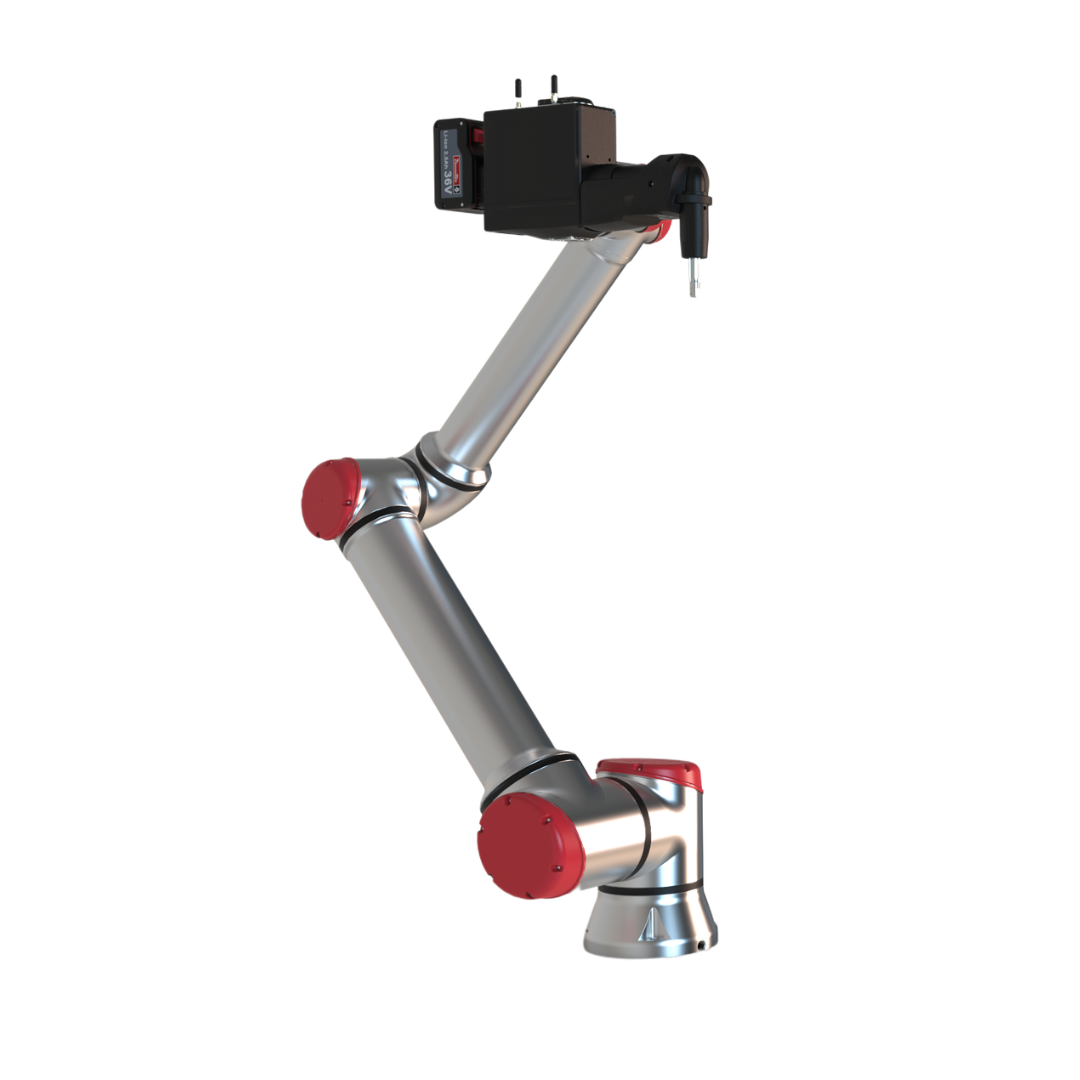

3D vision system made for tightening and drilling

ARG - Automated Robot Guidance was developed based on observations made on production lines: on many automated stations, the positioning of parts to be assembled is not repeatable and deviations of up to a several centimetres from the required positions can occur. To achieve better automation and precision, Desoutter adds Automated Robot Guidance to its light automation range: a precise 3D vision system, designed for tightening and drilling.

Automated Robot Guidance addresses industry challenges

Desoutter’s 3D vision system addresses a wide range of challenges faced by many industry players (only Stop & Go applications are eligible for the existing Desoutter solutions):

- Integration with existing systems

- Variability in lighting and environment

- Complexity of image processing

- Data overload

- Accuracy and reliability

- Scalability and flexibility

- Maintenance and required expertise

- High initial investment

All cases where the positions of tightening points are not repeatable may require the use of Automated Robot Guidance. It’s a major new step in optimising the tightening and drilling operations.