ARG - Guidage Robotisé Automatisé - est un système de vision conçu spécifiquement pour garantir les opérations de vissage et de perçage sur les lignes de production Stop & Go. Un système facile à utiliser qui établit une nouvelle référence en matière de précision pour le vissage et le perçage dans le guidage robotisé, en assurant la reprise d’alignement de l’outil en bout de bras.

En relevant le défi de la répétabilité et du positionnement des pièces sur les lignes de production.

Utilisez la vision 3D pour trouver les points de vissage/perçage et aligner automatiquement les trous ou les vis

Élimine le besoin de mécanismes coûteux, complexes et rigides

Grâce à un outil facile à installer, à utiliser et à entretenir.

ARG - Guidage robotisé automatisé en vidéo

Une solution intégrée par Desoutter

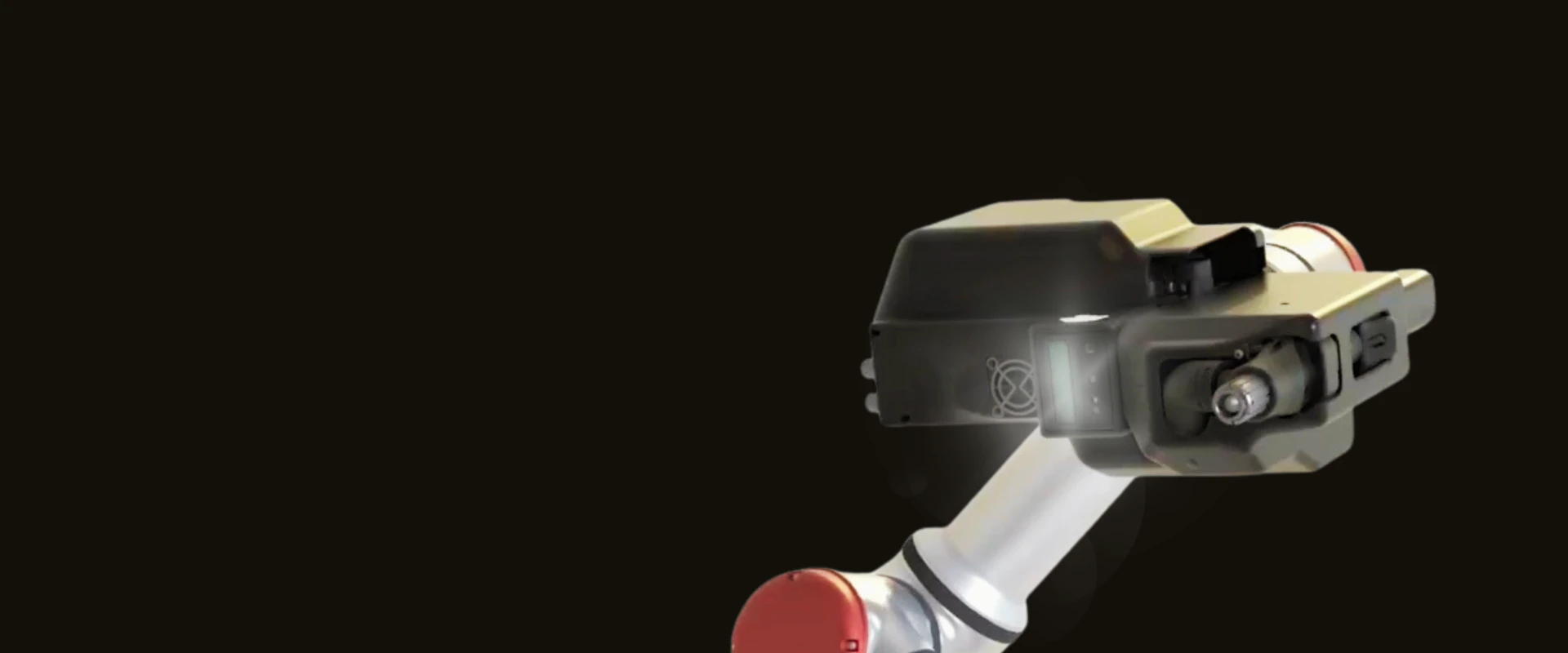

Un kit tout-en-un composé de 4 éléments

La caméra

La petite caméra peut capturer des images 3D nettes au plus près pour optimiser le process.

Le processeur

L’ordinateur équipé d’un GPU exécute le logiciel ARG qui utilise des modèles d’IA pour analyser les images 3D.

Le dispositif d'éclairage

Un équipement standard sur tous les modèles, conçu pour les environnements à très faible éclairage lors de l’assemblage.

Le logiciel

L’IHM garantit une autonomie complète des utilisateurs sur la plupart des utilisations. Pour les configurations plus complexes, un logiciel low-code dédié est également disponible.

La caméra

La petite caméra peut capturer des images 3D nettes au plus près pour optimiser le process.

Le dispositif d'éclairage

Un équipement standard sur tous les modèles, conçu pour les environnements à très faible éclairage lors de l’assemblage.

Le processeur

L’ordinateur équipé d’un GPU exécute le logiciel ARG qui utilise des modèles d’IA pour analyser les images 3D.

Le logiciel

L’IHM garantit une autonomie complète des utilisateurs sur la plupart des utilisations. Pour les configurations plus complexes, un logiciel low-code dédié est également disponible.

Conçu pour le repérage de points de vissage et de perçage non répétitifs

Positionnement global de l’assemblage

Le véhicule ou le convoyeur transportant l’assemblage d’un poste à l’autre effectue des arrêts à des positions imprécises.

Points essentiels

Vision 3D

Une détection de profondeur haute précision

Détection rapide par lots

Des dizaines de trous détectés en une seule prise d’image

Moins d'une seconde

Temps de traitement et d’envoi des coordonnées des points de vissage et de perçage

Robots compatibles

Tous les robots industriels et cobots

Un dispositif compact pour une vision élargie

- Caméra extra-compacte et légère installée directement sur l’outil.

- Performances garanties grâce au GPU et au logiciel d’analyse basé sur l’IA.

- Capacité à détecter différentes caractéristiques telles que des trous ou des vis prémontées.

Une vision 3D adaptée aux exigences de l’industrie

- Une caméra non conventionnelle, par sa compacité et sa précision.

- Utilisation de la technologie VCSEL pour une détection de profondeur haute précision.

Un projet ? Parlons-en !

Souhaitez-vous étudier l’intégration de l’ARG dans votre ligne d’assemblage ?

Un dispositif conçu pour la performance

- Détection par lots : une seule acquisition d’image pour détecter un mélange de trous et de têtes de vis dans une zone d’intérêt.

- Précision extrême avec 100 % des détections dans les tolérances de positionnement.

Un outil innovant basé sur l’IA

- Modèles d’IA offrant une analyse d’images extrêmement précise, adaptée à tous les types d’usage.

- Un système évolutif permettant de modifier facilement la conception des pièces et de dupliquer les configurations grâce à des modèles d’IA pré-entraînés, adaptés aux usages spécifiques.

Réduire le temps de programmation

- Un outil évolutif que les opérateurs peuvent configurer sur n’importe quelle ligne de production Stop & Go.

- Facile à installer, configurer et maintenir, pour une autonomie totale du client.

D’autres questions sur le guidage robot automatisé ?

Comment la vision améliore-t-elle les performances des robots ?

La vision améliore les performances des robots en fournissant des données spatiales précises, permettant un positionnement exact des outils en bout de bras. Elle accroît l’adaptabilité en permettant aux cobots de réaliser une variété de tâches sans reprogrammation.

Quelles sont les principales applications de la vision en robotique ?

Les principales applications comprennent l'automatisation des chaînes de montage, où la vision guide les robots dans le placement et la fixation des composants ; le contrôle qualité, où elle détecte les défauts et garantit la conformité des produits ; et la manutention, où elle facilite le placement avec une grande précision.

Quels sont les avantages des systèmes de vision pour les robots collaboratifs ?

Les avantages comprennent une précision accrue dans des tâches telles que l'assemblage et l'inspection, une sécurité améliorée grâce à la surveillance en temps réel de l'environnement et une plus grande flexibilité dans la gestion de tâches diverses et complexes. Les systèmes de vision permettent également aux cobots de travailler plus efficacement aux côtés des opérateurs humains.

Comment intégrer des systèmes de vision aux robots ?

L'intégration consiste à monter une caméra sur le robot, à calibrer le système de vision avec le système de coordonnées du robot, puis à programmer ce dernier pour qu’il interprète et exploite les données visuelles. Ce processus peut nécessiter un logiciel spécialisé ainsi qu’une expertise en robotique et en vision par ordinateur.

Quels facteurs faut-il prendre en compte lors du choix d’un système de vision pour robots ?

Les éléments à prendre en compte incluent la précision et la vitesse du système de vision, la compatibilité avec le matériel et les logiciels robotiques existants, la complexité des tâches à réaliser, ainsi que la capacité du système à fonctionner dans diverses conditions d’éclairage. Le coût et la facilité d’intégration sont également des facteurs importants.

Qu’est-ce que la vision 3D en robotique ?

La vision 3D en robotique consiste à utiliser des caméras stéréoscopiques ou de la lumière structurée pour capturer des informations de profondeur, permettant ainsi aux robots de percevoir et d’interagir avec leur environnement en trois dimensions. Cette technologie est essentielle pour les tâches nécessitant une grande précision et une perception spatiale avancée.