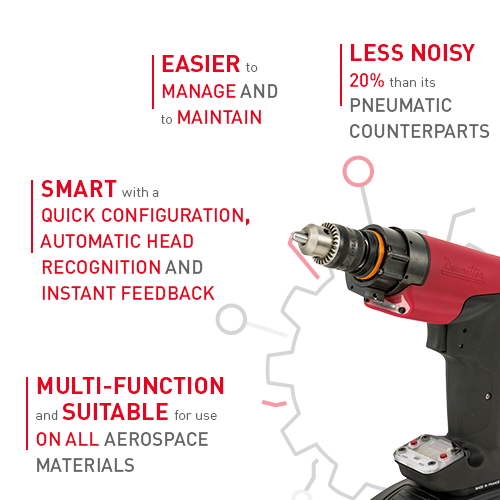

Not only is XPB the first battery drill fit for aerospace processes, it is also the first multifunction platform designed to take aerospace manufacture into the future!

Aerospace assembly is complex. It involves many different materials - metals, composites - and many different types of fasteners. As a result, workbenches are littered with different tools that have evolved to address each assembly task.

The result is far from ideal. Assembly line workers are constantly putting down or picking up tools, the air hoses get tangled or tripped over and restrict movement – plus it is incredibly noisy. On top of that, all these tools represent a significant capital outlay and a high cost of ownership because they all need regular calibration and maintenance. For a high-tech industry whose end products can hurtle through space, break sound barriers and defy gravity, it’s not a great advertisement.